export.technogen@gmail.com View Mobile Number

- Send SMS Send Email

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor |

| Feature | No Bottle - No Fill |

| Brand Name | Technogen Enterprise |

| Material | Stainless Steel |

| Click to view more | |

Product Details

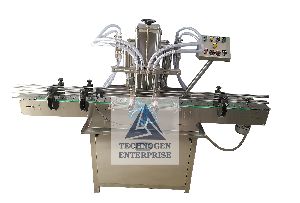

Technogen Enterprise based in Ahmedabad, Gujarat, India is the esteemed manufacturer, exporter, and supplier of the Automatic Double Head Auger Powder Filling Machine, boasting the advanced Model TGAPF-60. This dual head automatic auger filler is designed for high-speed powder filling applications, ensuring seamless and efficient filling processes.

Our Automatic Double Head Auger Powder Filling Machine features superior synchronization between the filling and indexing systems, guaranteeing precision and accuracy in every fill. Witness the remarkable output of up to 50 to 60 bottles per minute for 5 GMS and 10 GMS filling, streamlining your production line and maximizing productivity.

To ensure optimal control over auger rotation and filling, our machine is equipped with an Electromagnetic Clutch break system, delivering precise and consistent fills. Additionally, we offer the option to upgrade to a Servo motor with a driver for even higher precision, catering to your specific requirements.

Trust in the reliability and efficiency of Technogen's Automatic Double Head Auger Powder Filling Machine to optimize your powder filling processes. Experience the future of high-speed filling applications, ensuring superior performance and customer satisfaction.

Choose Technogen Enterprise for top-quality filling solutions. Contact us now to explore the full potential of our Automatic Double Head Auger Powder Filling Machine Model TGAPF-60 and elevate your filling operations to a new level of excellence. Upgrade to precision and reliability with Technogen today!

Salient Features:

- CGMP and compact model

- All contact parts in AISI 316L.

- Machine is constructed in AISI 304 with top plate is mild steel

- Works on Auger metric principle and auger rotation is controlled using electro magnetic clutch. As an optional, servo control system is available

- No Bottle – No Fill Mechanism.

- Bottle indexing is done using star wheel which result in to air saving thus utility

- Weight variation: Less than +/- 5.0 % subject to the powder nature, fill weight & speed.

- Minimum change parts, hence quick changeover.

- No Change Part require for change in bottle height

- Virtually no powder loss

- Variable speed for slat conveyor – The speed of the slat conveyor can be controlled with A/C variable motor thus falling of bottles is totally eliminated.

- No dripping – drip control mechanism to control dripping after completion of dosing.

- Lower cost of production – Since requirement of labour, space and support facilities is minimal.

- Simple operation – easy to operate & maintain

- Virtually maintenance free machine

- High operational comfort – Since all parts are easily accessible and controls are conveniently located.

- Long life – sturdy robust design, sophisticated manufacturing techniques and better material of construction ensures long and trouble-free life.

- Ease of maintenance – due to less number of moving parts.

Optional Items:

- Dust Extraction System

- Acrylic Safety Cabinet.

- Non Free flow Powder Feeding System.

- PLC – HMI Interface with Audit trail facility

- Servo filling head.

Applicable industries:

- Food

- Pharmaceuticals,

- Chemicals,

- Cosmetics

Looking for "Automatic Double Head Auger Powder Filling Machine" ?

Explore More Products