export.technogen@gmail.com View Mobile Number

- Send SMS Send Email

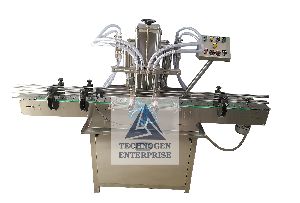

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor |

| Features | All contact part are made from SS 316L Material |

| Brand Name | Technogen Enterprise |

| Finishing | SS Mat Finishing |

| Click to view more | |

Product Details

Technogen Enterprise, based in Ahmedabad, Gujarat, India, is a renowned manufacturer, exporter, and supplier of a wide range of Double Cone Blenders, also known as Double Cone Mixers. These efficient and state-of-the-art machines are designed for homogeneously mixing dry powders and granules. The Double Cone Blender's most notable feature is its construction with high-quality materials. All contact parts with the mixing material are made from AISI 316L grade stainless steel, ensuring excellent corrosion resistance and material compatibility. The non-contact parts are made of AISI 304 stainless steel, providing robustness and durability to the machine.

The Double Cone Blender's design allows for optimal mixing efficiency, as two-thirds of the blender's volume is typically filled to achieve perfect mixing results. This design ensures that the material inside the blender is uniformly mixed, resulting in a consistent and homogenous final product.

The Double Cone Blender finds extensive use in various industries, including pharmaceuticals, food, chemicals, and cosmetics. Its versatility makes it an ideal choice for mixing a wide range of materials in these industries, ensuring consistent product quality and meeting stringent industry standards.

At Technogen Enterprise, we are committed to delivering top-quality Double Cone Blenders that excel in performance and reliability. Our machines are manufactured using the latest technology and adhere to the highest quality standards. Whether you need a Double Cone Blender for a small-scale operation or a large-volume production process, we offer various configurations to suit your specific requirements.

Choose Technogen Enterprise as your trusted partner for your Double Cone Blender needs, and experience the benefits of our advanced mixing technology and exceptional customer service. Contact us today to explore our range of Double Cone Blenders and find the perfect solution for your mixing applications.

Features:

- CGMP Model

- All Moving Parts of Double Cone Blender Are Covered with SS304 Covers.

- Safety Guards Made from SS304 Pipes Provided in Front of The Machine.

- Panel Of Double Cone Blender Is Fabricated from AISI 304 Material with Facility of Three Phase Indication, D.O.L. Tarter, Digital Timer & Amp Meter.

- As Per Customer Requirement Double Cone Blender Machine Will Be Provided with Left Side Drive or With Right Side Drive.

- The Conical Shape at Both Ends Enables Uniform Mixing & Easy Discharge.

- All contact parts are made of AISI 316L.

- Maximum Care Has Been Taken to Ensure Safe Operation of The Unit.

- Food Grade Rubber Gasket Will Be Used on Both Ends of Cone as Well As In Butterfly Valve.

- Inside & Outside of The Double Cone Blender's Cone Will Be Polished to The Mirror Finished. (All Safety Guards & Covers Made Out of SS304 In GMP Model as Required by You) In GMP Model

- The Conical Shape of Both Ends Enables Uniform Mixing and Easy Discharge

- Suitable Size of Butter Fly Valve at One End of The Cone Provided for Material Discharge & Hole with Open Able Cover Provided at Other End of The Cone for Material Charging & Cleaning.

- One Shaft With 03 Nos. Of Fixed/ Detachable Buffers with Mirror Polished Provided Inside the Cone.

Looking for "Double Cone Blender" ?

Explore More Products